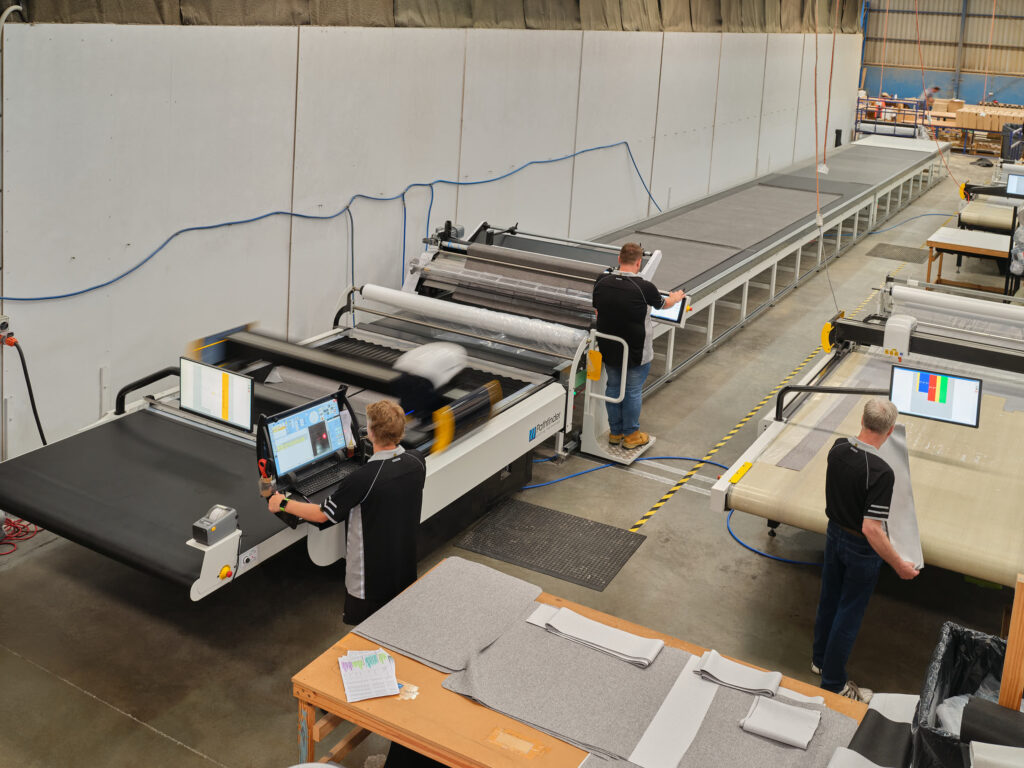

Contract Fabric Cutting

In the dynamic landscape of manufacturing, precision and efficiency play pivotal roles in determining the success of a project. This article explores the transformative benefits of opting for CNC fabric cutting services for fabrics and leather, shedding light on how this advanced technology can revolutionize the production process.

1. Unmatched Precision and Consistency

CNC fabric cutters bring a level of precision to the cutting process that is unparalleled. Computer-controlled systems ensure that each cut is precise, resulting in consistent and flawless patterns. This precision is crucial for industries where accuracy is non-negotiable, such as medical, sign making, fashion, automotive, and furniture manufacturing.

2. Enhanced Speed and Efficiency

The speed at which CNC fabric cutters operate is a game-changer in the manufacturing world. Automated cutting processes significantly reduce production time, enabling businesses to meet tight deadlines and respond promptly to market demands. Faster production cycles lead to increased overall efficiency and productivity.

3. Customization Without Compromise

One of the standout features of CNC fabric cutting is its ability to handle intricate designs and custom patterns with ease. Whether it’s complex shapes, unique sizes, or personalized detailing, CNC fabric cutters can execute the most intricate designs without compromising on accuracy or speed. This opens up a world of creative possibilities for designers and manufacturers.

4. Optimized Material Usage and Waste Reduction

CNC fabric cutters are programmed to optimize material usage, minimizing waste. This not only contributes to cost savings but also aligns with sustainability goals. The reduction in material waste is not only economically beneficial but also environmentally responsible, making CNC fabric cutting a choice that supports eco-friendly manufacturing practices.

5. Cost-Effective Solutions for Businesses

Outsourcing fabric and leather cutting to CNC services can be a cost-effective solution for businesses. While initial setup costs may be involved, the long-term benefits, including reduced labour costs, minimized errors, and increased production speed, result in significant cost savings over time. This makes CNC fabric cutting a wise investment for businesses aiming to enhance their bottom line.

6. Streamlined Production Processes

CNC fabric cutters streamline the entire production process, from design to final product. Integration with computer-aided design (CAD) systems ensures seamless transitions from concept to execution. The elimination of manual cutting processes reduces the likelihood of errors, contributing to a more streamlined and efficient production workflow.

Embracing CNC fabric cutting services for fabrics and leather is a strategic move towards achieving precision, efficiency, and cost-effectiveness in manufacturing. As technology continues to advance, integrating CNC fabric cutters into production processes proves to be a transformative step that positions businesses at the forefront of innovation in their respective industries. Consider the myriad benefits outlined above when contemplating your next fabric and leather cutting venture..